Raising the Bar in Hygiene Testing: Inside the Science of the Kikkoman A3 Lumitester

When it comes to restoring water or fire-damaged buildings, cleaning isn’t just about appearances. It’s about proving — scientifically — that an environment is safe, hygienic, and ready to be reoccupied. For decades, ATP hygiene testing has been one of the most widely used methods to provide that proof. But as the restoration industry evolves, so too must the tools we use to validate our work.

Enter the Kikkoman A3 Lumitester, a device that’s not only changing the conversation around ATP testing but also setting a new standard for hygiene verification.

What is an ATP Test?

An ATP test is a hygiene monitoring method that measures organic residues on surfaces by detecting adenosine triphosphate (ATP).

The Science Behind ATP Testing

ATP (adenosine triphosphate) is an energy-carrying molecule found in all living cells. Because it’s present in bacteria, food residue, and organic matter, ATP testing has long been used as a quick way to measure hygiene levels on surfaces. A surface with high ATP levels means poor cleaning; a low level indicates effective sanitation.

But here’s the catch: ATP is unstable. During normal processes like cleaning, heating, or even natural degradation, ATP breaks down into ADP (adenosine diphosphate) and AMP (adenosine monophosphate). Conventional ATP-only testing methods fail to detect these breakdown molecules. The result? Surfaces that still contain contamination might pass as “clean” under standard ATP-only testing.

For restoration, this isn’t just a lab detail — it’s a frontline issue. False passes risk leaving behind microbial contamination that can compromise indoor air quality, trigger health complaints, and increase liability for technicians.

A Closer Look at ATP, ADP, and AMP

Let’s break it down further:

- ATP (Adenosine Triphosphate): Think of this as the cell’s “charged battery.” It has three phosphate groups, storing energy used by living cells.

- ADP (Adenosine Diphosphate): When ATP is used, it loses one phosphate group and becomes ADP — a partially drained battery, but still traceable.

- AMP (Adenosine Monophosphate): When ADP is broken down further, it becomes AMP — the last remnant of the energy process.

Here’s why this matters: if you only test for ATP, you might miss the breakdown molecules (ADP and AMP), meaning contamination lingers undetected. Kikkoman’s A3 Lumitester is currently the only portable device that can measure all three molecules, providing a much more accurate hygiene picture.

Understanding ATP Swabs

Types of ATP Swabs

ATP testing relies on special swabs coated with a reagent. When swabs collect organic residue from a surface, the reagent reacts with ATP (and in Kikkoman’s case, also ADP and AMP), producing light that the device measures as Relative Light Units (RLUs).

How to Use ATP Swabs

- Collect a sample by swabbing a designated surface area.

- Insert the swab into the device.

- Wait for the reading.

- Compare the result against your pass/fail threshold to determine cleanliness.

The Process of ATP Surface Testing

Steps in an ATP Surface Test

- Select a high-risk or representative surface.

- Use a sterile ATP swab to sample the area.

- Activate and insert the swab into the reader.

- The device measures the light reaction and provides an RLU score.

- Compare the RLU against your preset pass/fail limit.

Key Equipment and Materials

- ATP testing device (e.g., entry level testing kits Kikkoman A3 Lumitester or Hygiena Ensure Touch)

- Compatible ATP swabs

- A defined testing protocol with established thresholds

Challenges and Considerations

Factors Affecting ATP Testing Results

- Surface type: Porous vs. smooth surfaces can influence swab recovery.

- Moisture levels: Residual moisture can affect readings.

- Temperature and handling: ATP degrades quickly; testing must be done promptly.

Common Misconceptions About ATP Testing

- ATP tests don’t directly measure bacteria; they measure residual organic matter (which includes bacteria, but also food and other debris).

- Passing an ATP hygiene test doesn’t mean “sterile” — it means the surface is within an acceptable cleanliness range.

Why the Kikkoman A3 Lumitester is Different

The Kikkoman A3 Lumitester closes the gap by detecting ATP, ADP, and AMP. This ensures no hidden residues are missed — crucial when you’re signing off a job where health risks and client trust are on the line.

Key features include:

- Triple detection (ATP + ADP + AMP) — unmatched coverage compared to ATP-only devices.

- Fast results in just 10 seconds.

- 2x AA batteries — no waiting for recharging in the middle of a job.

- Extendable swab holder — ideal for hard-to-reach areas on ceilings, ducting, or cavities.

- Lower entry price in Australia — more accessible for restoration companies of all sizes.

The Sausage Test

Science doesn’t always have to be serious. To demonstrate just how responsive the Lumitester is, Kikkoman put it through the “sausage test” — and the results are eye-opening.

This demonstration makes a serious point: Kikkoman’s detection capability picks up residues that ATP-only devices miss.

Creating a Pass/Fail System is Simple

Testing only matters if you can set clear thresholds for action. Fortunately, Kikkoman has made this process straightforward. Restoration businesses can establish their own pass/fail criteria based on surface type and cleaning goals.

Kikkoman provides a step-by-step instructional guide on how to configure thresholds, interpret results, and make data-driven hygiene decisions. This ensures consistency across technicians and defensibility in reporting to insurers or clients.

A Case Study from the University of Wisconsin-Madison

Link to study: https://www.linkedin.com/pulse/setting-practical-passfail-limits-hygiene-184rc/

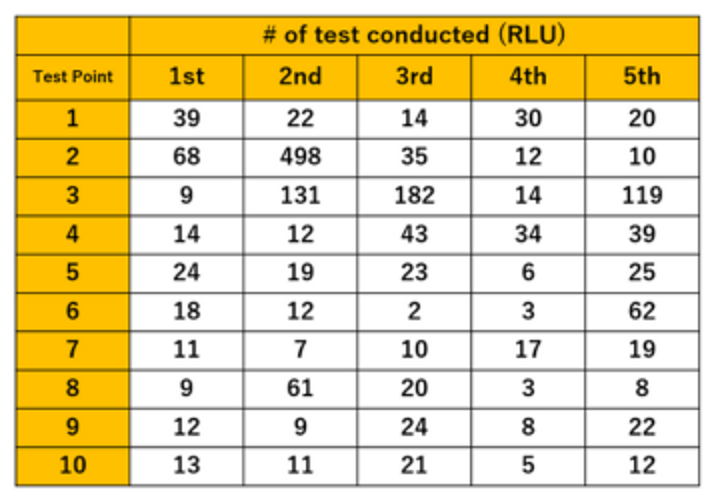

To get a practical understanding of pass/fail limits in use, The University of Wisconsin-Madison completed APT testing using the Kikkoman A3 to show their results in a fair and realistic way. In order to do this, they completed the following steps.

Step 1: Testing Spots

They picked 10 places to test

- 5 inside equipment that cleans itself (called Clean-in-place systems or CIP systems)

- 5 from parts that are cleaned manually or separately (called Clean-out-of- place of COP systems)

Each spot was tested before and after cleaning to show how much dirt (ATP) was there.

Step 2: Data Collection

Each testing spot was tested 5 times to see how much the readings varied. This gave them a small batch of results for each location which presented the ups and downs of real life cleaning.

Example of their Data Collection

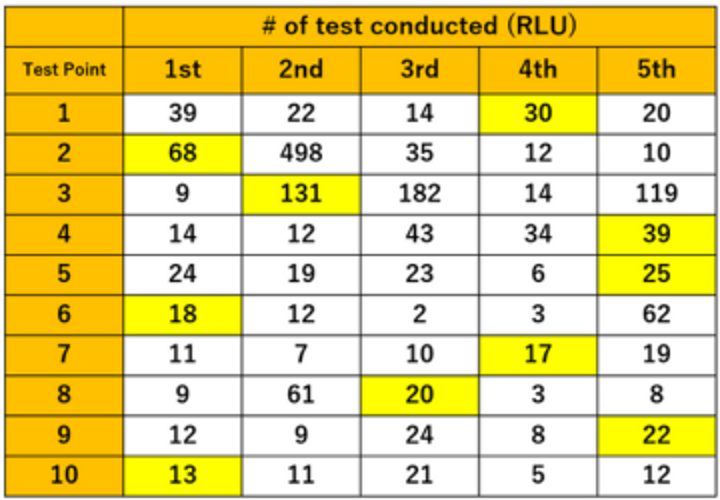

Step 3: Set a Pass Limit that’s realistic

Instead of selecting a random number, they looked at their five test results for each spot and chose the second highest reading. That number became the “pass limit”.

Why the second highest? Because it ignores on extreme bad reading but still keeps the standard realistic.

Example:

- One surface might have a pass limit of 30 RLU

- Another, 135 RLU

- Another, 15 RLU

(RLU = Relative Light Units — the number the ATP tester gives.)

This method means about 80% of future tests will pass, which is strict enough to keep things clean but not so hard that staff get discouraged.

Setting Pass Limit

Step 4: Check It Works

After setting those limits, they keep testing to make sure;

- Cleaning is done right – results should be under the limit.

- If everything passes easily, perhaps the limit is too generous.

- Alternatively, if everything keeps failing, the limit is too tough.

The goal is to find the sweet spot that is safe, achievable and motivating.

Step 5: Review When Things Change

The pass/fail criteria is not static and when change occurs, new testing is required. If you switch cleaning products, methods or suppliers, you need to retest and reset the limits. Different detergents or tools can change how clean things get.

Looking at the Competition: Hygiena Ensure Touch

In order to truly understand what the Kikkoman A3 Lumitester can offer technicians in the field, we compared it with one of the leading ATP testers on the market: the Hygiena Ensure Touch. Hygiena has long been the go-to brand in food safety and healthcare, but when held side by side with Kikkoman, the differences are clear.

Comparison: Kikkoman A3 Lumitester vs. Hygiena Ensure Touch

| Feature | Kikkoman A3 Lumitester | Hygiena Ensure Touch |

|---|---|---|

| Detection Capability | ATP + ADP + AMP (triple detection) | ATP only |

| Measurement Time | ~10 seconds | ~30 seconds |

| Power Source | 2x AA batteries (field replaceable) | Rechargeable battery (requires downtime) |

| Ease of Use | Compact, extendable swab holder | Larger touchscreen, standard swabs |

| Data Reliability | Captures contamination missed by ATP-only testing | Higher risk of false negatives |

| Portability | Slimline, fits in restoration kit | Bulkier unit |

| Price (Australia) | Lower entry price | Higher entry price |

| Limitations | Newer to the restoration market; brand awareness still growing | More expensive; ATP-only limitation |

What This Means for the Restoration Industry

For restorers, this isn’t just a technical debate — it’s a question of confidence and practicality. Hygiena’s system has history, but Kikkoman’s triple detection, speed, and lower entry price provide a powerful edge.

By adopting Kikkoman, restoration businesses can:

- Deliver scientifically robust proof-of-clean for clients and insurers.

- Reduce the risk of false passes that undermine remediation efforts.

- Build client trust by providing transparent, data-backed reports.

- Differentiate themselves with a cutting-edge technology that aligns with best-practice hygiene verification.

For an independent perspective, industry professionals can also review this comparative article on hygiene monitoring devices, which reinforces why Kikkoman’s broader detection model is winning attention globally.

Future of ATP Testing in Hygiene Monitoring

Innovations in ATP Testing Equipment

The move from ATP-only to ATP + ADP + AMP detection is a breakthrough. Future devices may integrate wireless data syncing, cloud reporting, and AI-driven threshold setting to further simplify hygiene verification.

Integrating ATP Testing into Routine Practices

For the restoration industry, ATP testing is moving from “nice-to-have” to essential validation. Embedding testing into every project — from strip-outs to final clearance — ensures consistent quality control and stronger insurer confidence.

Conclusion

ATP testing remains one of the most reliable and practical hygiene test methods available. But by evolving the science to detect not just ATP, but also ADP and AMP, the Kikkoman A3 Lumitester is more than just another ATP meter. It’s a disruptive tool that gives restoration professionals a clearer, faster, and more affordable way to validate their work. In an industry where trust, safety, and compliance are everything, having the right science behind your results makes all the difference.

Recent Posts

-

Restoration Equipment Maintenance: Best Practices for Longer-Lasting Gear

In restoration, your equipment isn’t just “tools of the trade” — it’s your reputation, your profitab …28th Jan 2026 -

Flood Preparation: Get Ready for the Next Event

How to Prepare for a Flood: Preparation & Response Guide for Restorers Supporting Australian restora …15th Jan 2026 -

Start the Year Strong with Our Restocking Service

Because the busiest season is when you need the fewest surprises. The new year is already in full sw …3rd Jan 2026