Professional Air Cleaner TAC 3500

Professional air purification for every requirement: From the construction site and asbestos abatement including to hygiene-sensitive areas and cleanrooms – all with one device

Trotec TAC 3500 Machine comes included with:

- 1 x G4 Pre Filter

- 1 x F7 Fine Dust Filter

- 1 x HEPA H14 Filter

Top quality engineering for full air purity at all times –

the commercial air cleaner of the TAC 3500 makes it possible

The TAC 3500 allows for such a variable range of applications like probably offered by no other air cleaner on the market: from "standard construction sites" over asbestos abatements to hygiene-sensitive areas or virus filtering, and even in cleanroom environments – and all that with only one device!

In addition to modularly combinable filter elements, the basis of this high variability of applications is especially the unique Vario-shift function thanks to which the filter chain can be flexibly configured wither with a terminal fan or HEPA filter as is for example prescribed for cleanroom environments.

Can be flexibly equipped with filter combinations tailored to the individual requirement

With dust class H this efficient air cleaner is the perfect solution for air extraction and cleaning of manifold large-volume work spaces with contaminated air.

Furthermore the TAC 3500 convinces by its possibility of combining different filter modules tailored to your need, by means of which an optimum filter chain for any level of room air contamination can be compiled.

The high-performance filter of class H14 for effective virus filtering – the TAC 3500 can be assembled with the ideal filter combination for every application.

Advantage Vario-shift function – unique in the world

Conventional air cleaners with inflexibly arranged filter ladders can well be used in construction zones, but are completely unsuitable for renovation work in cleanroom environments and therefore not permissible there. Because of the operational requirements of terminal high-efficiency particulate air filters in cleanroom surroundings the HEPA filter has to be downstream of the fan as the last link at the end of the filter chain.

Neat: All in one according to construction site & cleanroom standards!

A filtration series that is inflexibly arranged including a terminal high-efficiency particulate air filter as that prescribed for cleanroom environments, on the other hand would be completely unusable from an economical point of view for restoration work in standard environments involving mould infestation, since the fan would then be contaminated with spores and would have to be elaborately cleaned and disinfected every time.

However, it has not been possible so far to flexibly cover these two areas with only one air purification unit in a convenient fashion and without the use of additional attachment parts.

Thanks to the globally unique Vario-shift function, Trotec's TAC air cleaners can, by contrast, be variably adjusted for all application scenarios and in line with the regulations.

As the only portable air cleaner on the market, only TAC devices from Trotec are equipped for a fast change of position of fan and HEPA unit, meaning you can re-arrange the filter ladders in line with demand in the required sequence for standard or cleanroom applications at any time.

A few practical benefits:

- Professional quality “made in Germany” – originally produced by Trotec

- Unique in the world: Variably applicable for building site and cleanroom renovations with only one device

- Dust class H, approvable for asbestos abatement as per TRGS 519

- Already prepared for future directives of the (German) employer's liability insurance association regarding the use of portable air purification equipment

- Vario-shift function to adapt the use of the filter ladder with terminal fan or HEPA filter

- Monoventic regulator for precise and infinitely adjustable amounts of air

- Visual and acoustic pre- and main filter change indicator

- Extremely mobile by carrying handle and swivel casters

- Simple filter change due to quick top unlocking

Simple handling, effective air purification

These easily portable and ready-to-connect professional device with robust metal housing was especially designed for the rough everyday work on ever-changing construction sites

Whereas fan and filter units are accessible for configuration adjustments in a well-protected place behind easily unlockable revision panels, the operating elements mounted on the exhaust side provide direct access for adjustment processes:

- Two separate, sensor-supported pre- and main filter change indicators, both visual and acoustic, report a necessary filter change.

- For adjusting the air volume required, it can be steplessly adapted via Monoventic controller

- The operating control lamp indicates proper operation

- An integrated operating hours counter makes it possible to record the operating period and maintenance scheduling

The optimum solution for any air purification application

Air purification in the construction sector

Many building activities cause high concentrations of dust, not only when using angle grinders or during blasting, chiselling or demolition operations, but also when mixing dry mortar, spackle or tile cement. The TAC 3500 reliably filters construction dust in continuous operation from the air and alarms you automatically, visually and acoustically, when a filter change is necessary.

Air purification for painting work with airless paint spraying systems

By assembling the TAC 3500 with a special spray paint filter, the room air not only remains free from paint particles, but also the quality of the paint surface is improved by the use of a filter.

Mould remediation and asbestos abatement

Especially critical are dusts from quartziferous stones, artificial mineral fibres, wood, cellulose and asbestos. What adds to this is the pollution with spores, allergens and microfibres, f.i. in the building, insulation layer or mould fungus restoration. With the TAC 3500 you are on the safe side, as this air cleaner is provided with dust class H and can be approved for asbestos abatement in compliance with TRGS 519.

Cleanroom renovations as well as microbial and virus air purification

Via Vario-shift function the TAC 3500 can be variably configured with a terminal HEPA filter as is prescribed for cleanroom environments. If required, the HEPA filter compartment can also be equipped with an H14 filter to ensure effective separation of viruses and other airborne pollutants in the particle range of 0.1 to 0.2 µm.

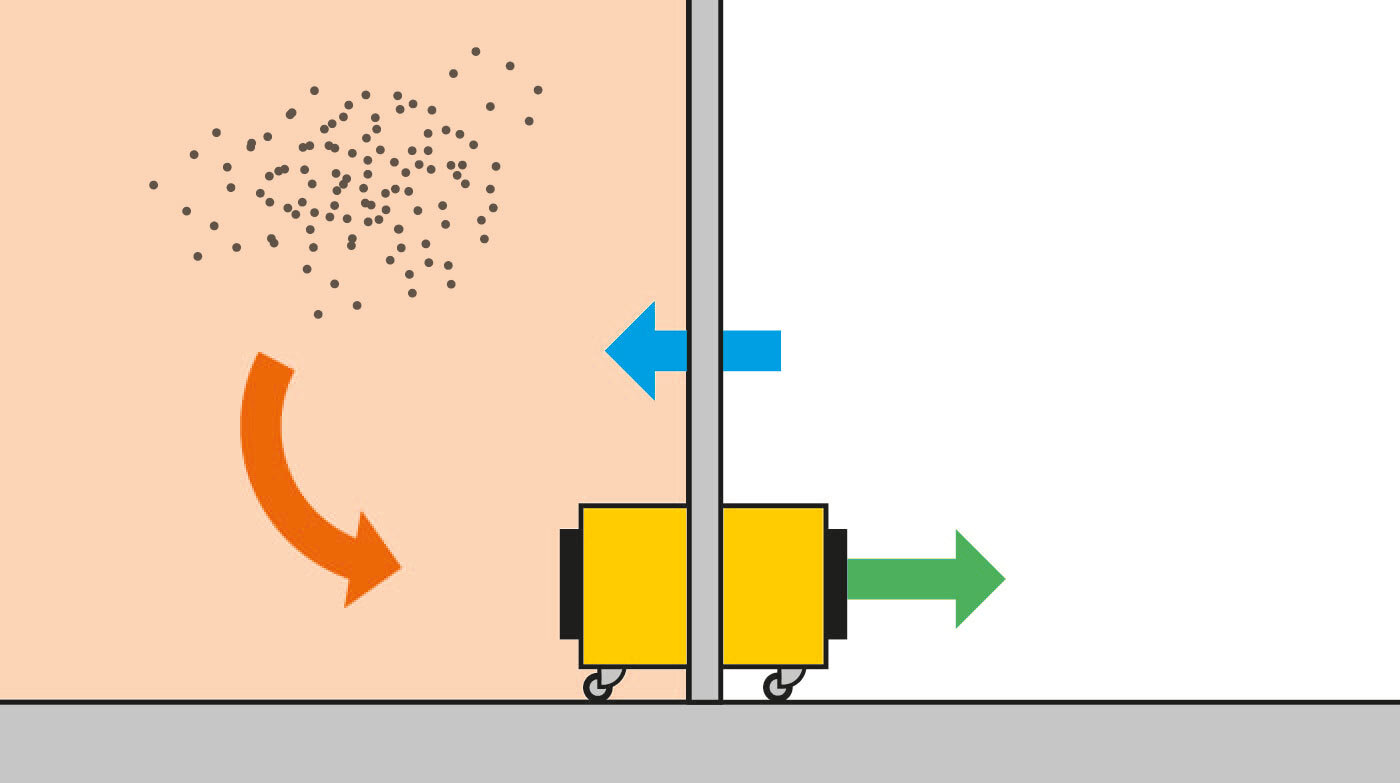

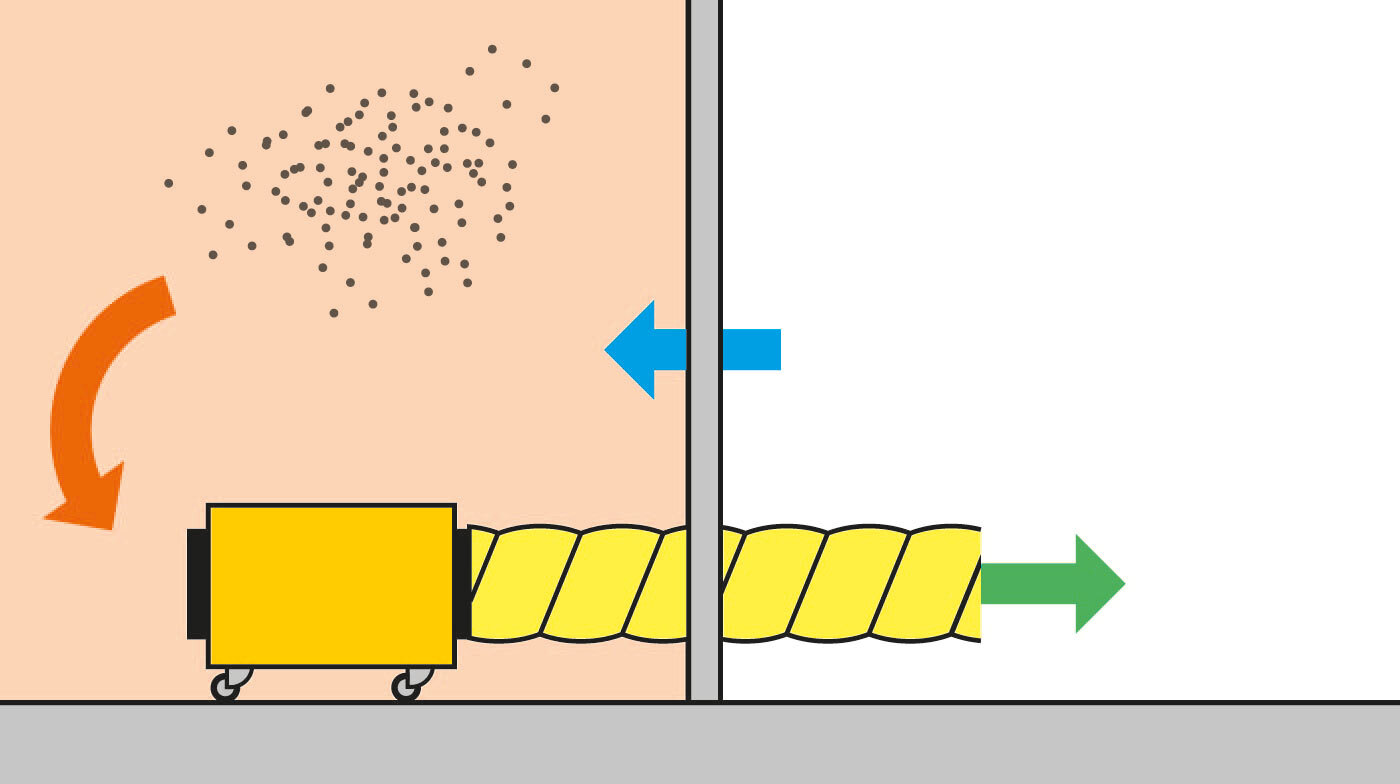

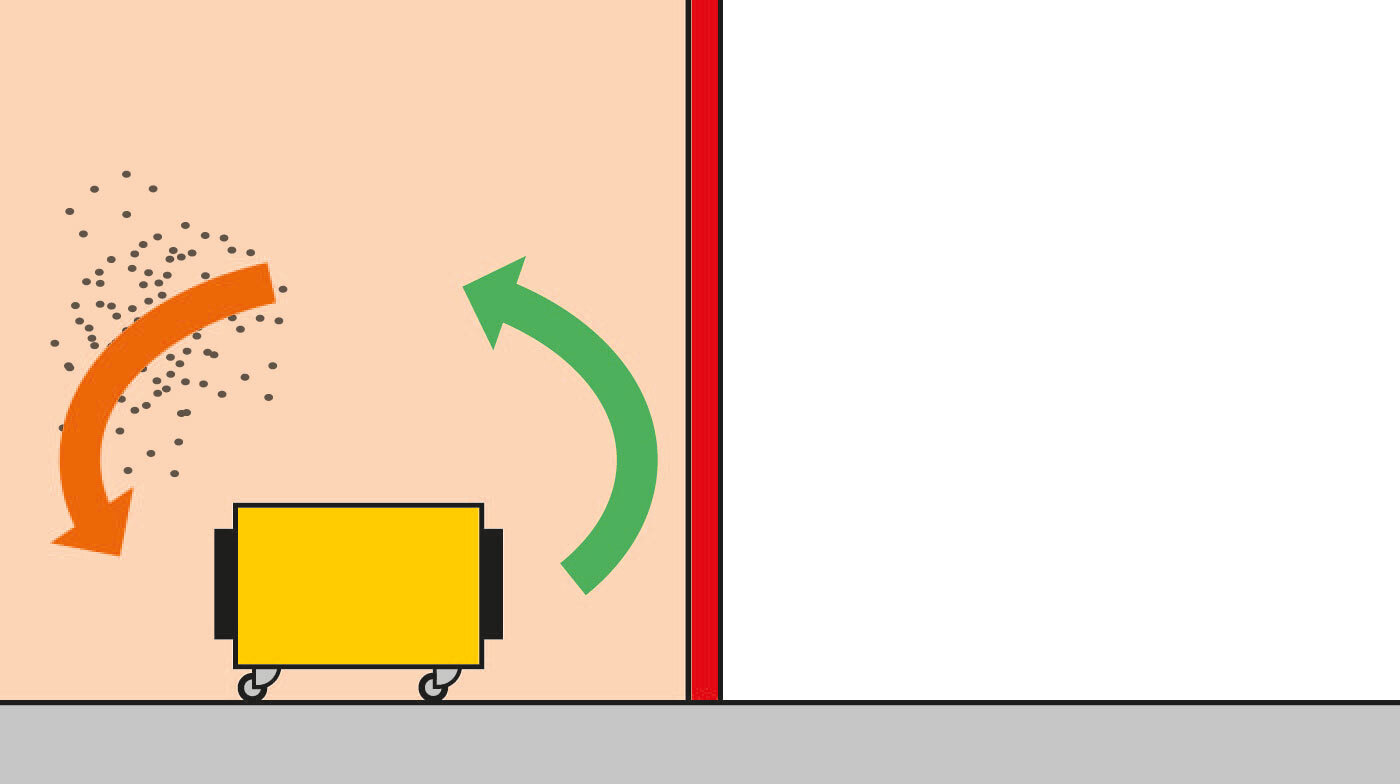

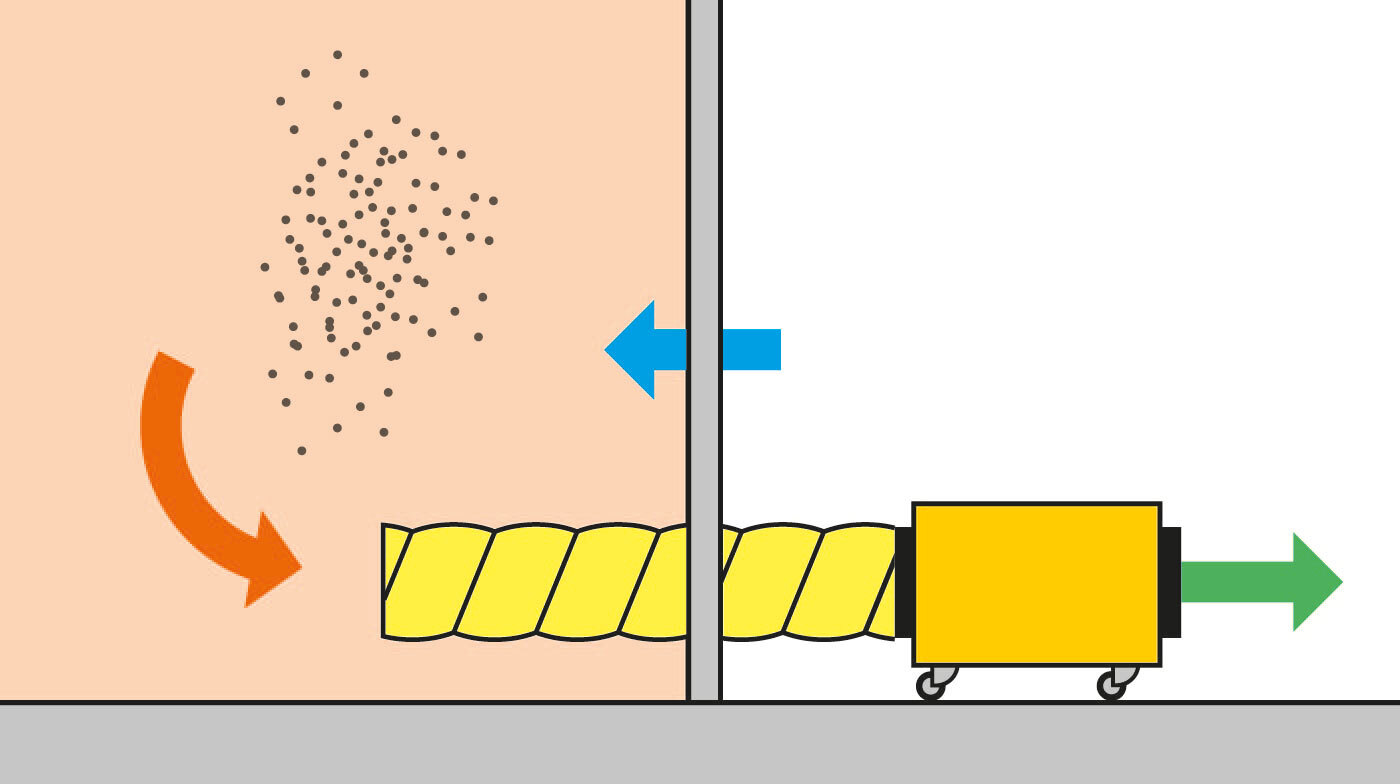

n the case of simple applications, TAC air cleaners can be placed directly in the doorway. Alternatively, the air can be led to pollutant-free areas using hoses. In addition to the ones shown here, many other variations are possible with the flexibly applicable TAC air cleaners.

Virus filtration also possible with commercial air cleaners!

For the H13 HEPA filter compartment of all professional air cleaners of the TAC series, also high-performance filters of class H14 as consumables for virus filtering are available as of now.

These final filters for cleanrooms of classes ISO 4 and ISO 3 feature a separation efficiency of 99.995% at a particle size of 0.1 to 0.2 µm.

Viral strains such as SARS-CoV, MERS-CoV or SARS-CoV-2 (Covid-19) show similar particle sizes, recent studies for example specify the particle size of the coronavirus to 120 to 160 nanometres, i.e. 0.12 to 0.16 µm.

Such particle sizes can be effectively separated by means of the H14 filters, especially since viruses in the air generally occur in combination with saliva or suspended matters as larger conglomerates.

All H14 filters meet highest quality standards that are mandatory in particular for sensitive applications in bacteria and virus filtering:

- Each filter is tested and receives an individual serial number

- The test report is enclosed as certificate in duplicate with every filter package

- The customers can store the original copy of the certificate and attach the copy to the device, if required.

- Tests are carried out in compliance with EN 1822 and DIN EN 60335-2-69

Maintaining pressure with TAC in doorway or dust protection wall.

Maintaining pressure with TAC in room and air hose.

Air purification in sealed off area via air circulation.

Maintaining pressure outside of room via air hose.

Protective excess pressure ventilation of rooms located in contaminated areas