MOIST 350 B - Portable Moisture Measuring System for non-destructive moisture measurement and moisture mapping

This kit includes:

The microcontroller based device works with the robust microwave sensors of MOIST xM-series with different penetration depths, manufactured according to industrial precision standard. The sensor calibration is carried out in accordance to the WTA rules. The direct comparison of the measured values of the various sensors is possible, even if relative measurements were used without calibration.

Internal data processing enables visualisation of moisture maps directly in the handheld, i. e. at the place of measurement. Statistical parameters support the analysis. Referencing to destructive measurements can be accomplished in the software.

The microcontroller based device works with the robust microwave sensors of MOIST xM-series with different penetration depths, manufactured according to industrial precision standard.

Internal data processing enables visualisation of moisture maps directly in the handheld, i. e. at the place of measurement. Statistical parameters support the analysis. Referencing to destructive measurements can be accomplished in the software.

Moisture measurement becomes very simple by menu-guided operation. Up to 1 million readings can be saved in up to 128 measuring arrays. The data transfer to software MOISTANALYZE for graphical processing is carried out easily by USB interface.

Please Note: The handheld has a color display so that the measurement results can be visualized graphically and displayed directly in the handheld device. The measuring heads of the MOIST 350 B have an additional relative curve for measuring building materials with a medium oven-dry density.

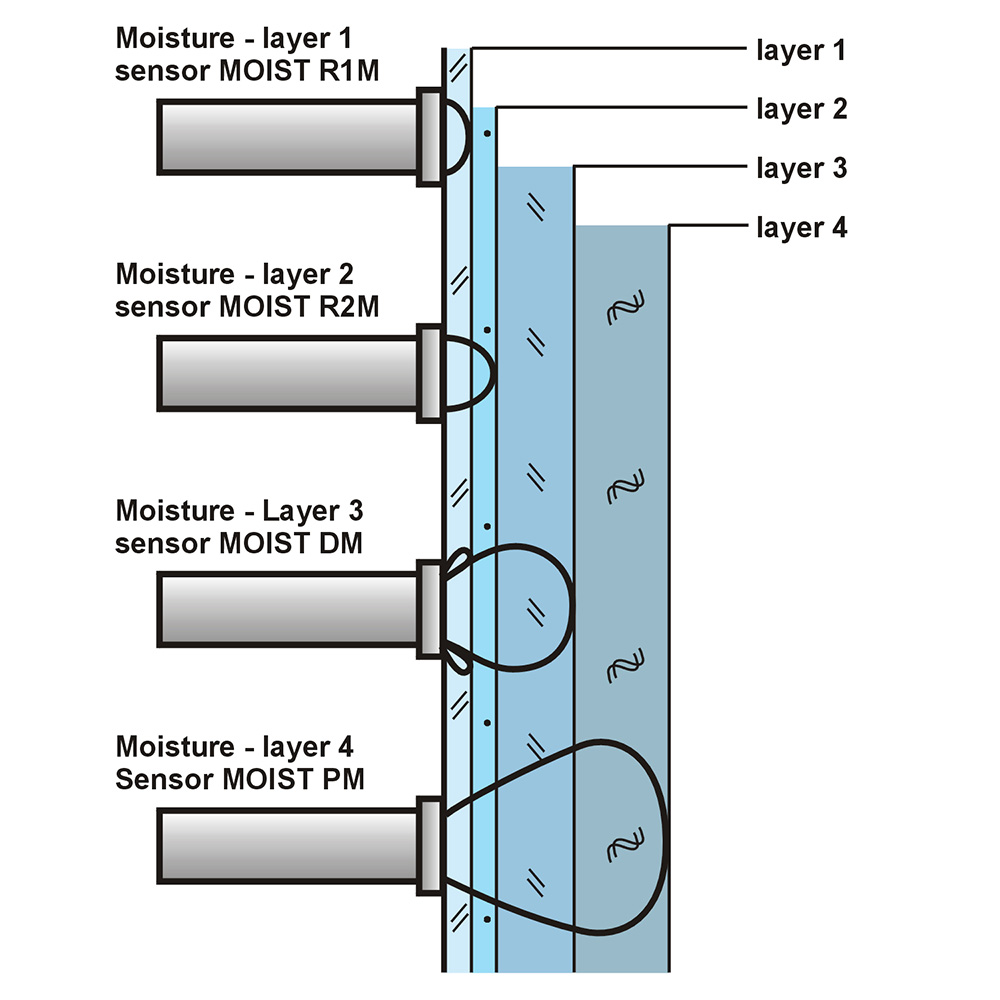

Layer 1. 2 to 3cm deep

Layer 2. 5 to 7cm deep

Layer 3. 10 to 11cm deep

Layer 4. 25 to 30cm deep

Microwave Moisture Measurement Technology

The absolute and relative moisture content of concrete structures is very important for the ability to apply coatings and the functional control of hydrophobization. The moisture status is just as important when assessing the condition of concrete structures before planning structural improvements and reinforcements - especially if corrosion due to chloride entry or carbonation is suspected.

For these applications, the non-destructive MOIST technology can be used excellently for comprehensive moisture mapping. The results correlate very well with the results of other NDT methods for structural diagnosis. Moisture damage can be easily differentiated from structural influences such as reinforcing steel.

With the hand-held device MOIST 350 B in conjunction with the microwave sensors MOIST R1M, MOIST R2M, MOIST DM, and MOIST PM, both absolute and relative humidity distribution can be recorded with high precision, quickly and representatively.

By comparing the moisture distributions at different layer depths, a moisture gradient in the depth direction can also be specified. For this purpose, the moisture measurements should be carried out with multiple sensors.

The results of the absolute moisture measurements agree excellently with reference measurements carried out destructively by core drilling and subsequent kiln drying.

Microwave moisture measurement methods, which belong to the category of dielectric measurement methods, are particularly suitable for this. Dielectric moisture measurement methods are based on the outstanding dielectric properties of water. Water is a polar molecule. The centers of charge of hydrogen and oxygen ions do not coincide locally within the molecule. They form a dipole. That's why the water molecule aligns itself in an externally applied electric field and is polarizable. If an alternating electromagnetic field is applied, the molecules begin to rotate at the frequency of the field. At high frequencies, only the water molecules can follow the exciting field. The dielectric effect is very strong in water, but much smaller in most solids. Because of the large difference between these values, even very small amounts of water can be easily detected.

For physical reasons, microwave moisture measurements have a number of significant advantages over other measuring methods:

- Accuracy

- Speed and therefore usability on moving measured goods

- Choice of recording large or small measuring volumes

- Hardly any cross-sensitivities due to the close interaction between microwaves and water

process-proof feasibility

- Scalability in their sensitivity range

Fields of application

Materials:

- wood

- building materials, walls

- granular materials

- food

- Compost

- organic materials

- other materials on request (customer specific)

Leakage detection:

- Quasi three dimensional moisture measurement